This marks the second post in our series on the importance of safe workplaces in San Antonio and the state of Texas. This time, we discuss one of the most common and useful heavy equipment found in many workplaces; the forklift. It’s important that you speak with a personal injury lawyer in San Antonio if you were injured in the workplace.

Forklifts Prevent Injury When Used Safely

One of the most important and useful machines in many workplaces in a number of industries, such as the construction, warehousing, and manufacturing sectors, is the trusty forklift. Unfortunately, many employers and shop managers seem to view the forklift as an everyday, common machine, like a sewing machine or a hammer, when it is much heavier and more capable of serious damage to equipment and injury to workers.

When used properly, a forklift is a very useful tool that can help workers in many workplaces from incurring serious injuries by limiting the need for lifting heavy objects. At the same time, however, while forklifts can reduce the need for “heavy lifting,” so to speak, they are also themselves quite large and very heavy, and they carry numerous safety risks to virtually every worker in the shop. Everyone in a workplace that uses a forklift should be properly trained and fully aware of the potential danger. Of course, everyone in the workplace who is expected to operate a forklift should be properly trained to do so, but all other workers in the shop should also be trained to work safely in the area surrounding the forklift.

While many employers and shop managers seem to treat the forklift as something of an afterthought, and they will throw almost anyone in the driver’s seat to operate one, sometimes without basic Personal Protective Equipment, like a hard hat and gloves, this is never a good idea. The reality is, forklifts are potentially hazardous to operate; so much so that the Occupational Safety and Health Administration (OSHA) Code has an entire subsection that covers nothing but forklifts, under the section entitled Powered Industrial Trucks. Forklift regulations should be understood by everyone, including those who operate one and those working around them. After all, even some of the smallest forklifts available still weigh more than three tons, making them potentially very dangerous.

The Importance of Knowing OSHA Forklift Regulations

According to OSHA regulations, every forklift operator must be over the age of 18 and they must also be specifically trained to operate a forklift. That is because a forklift that is operated correctly is no more dangerous than any other piece of heavy machinery. ON the other hand, if the operator is not properly trained and certified, injuries and death are far too common. Based on data provided by the Bureau of Labor Statistics (BLS), nearly 20,000 workers are seriously injured in forklift accidents every year, with about 100 of them injured fatally.

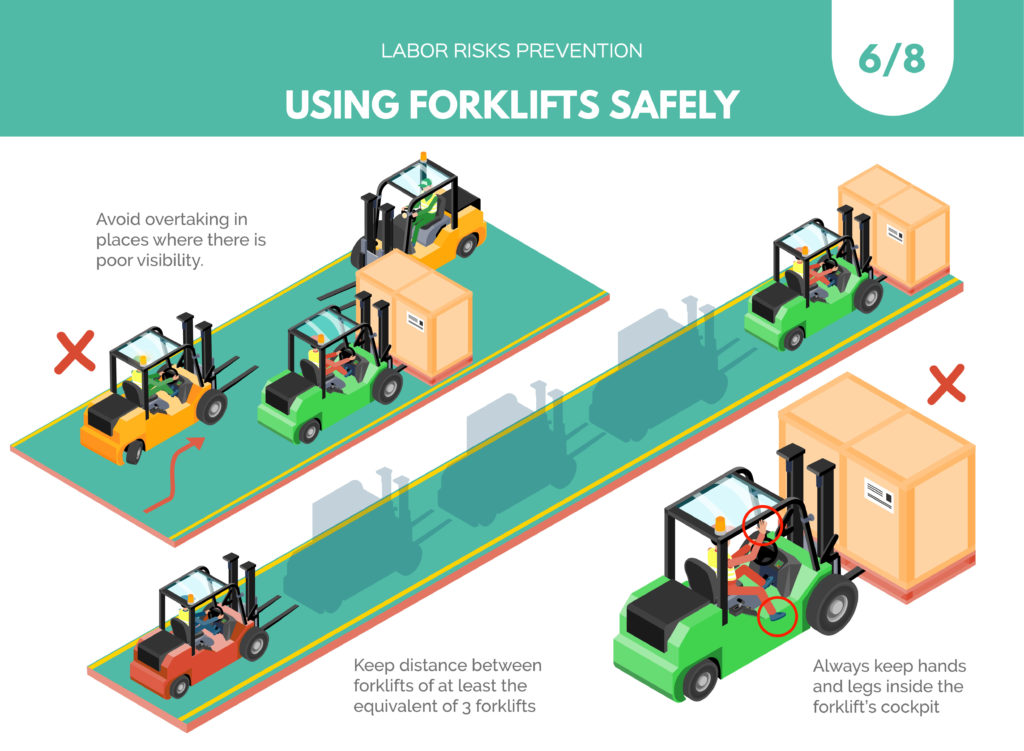

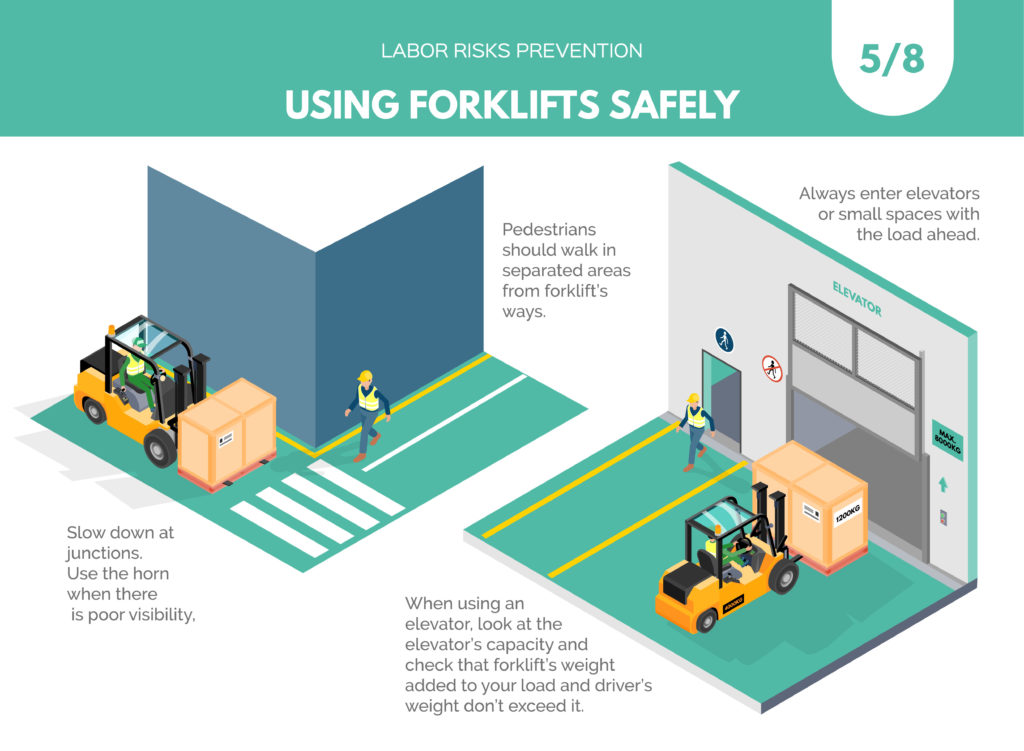

One of the most common factors present in most forklift accidents is speed; in many instances, the operator moves the forklift too fast based on the conditions present in the workplace. Given that nearly one out of every five fatalities from a forklift accident involves a worker who was on foot, it is necessary that forklift operators be extra careful at intersections and blind spots, and that pathways for the forklift to travel be clearly marked. That means all workers at the site should be properly trained as to how they can avoid being hit by the forklift.

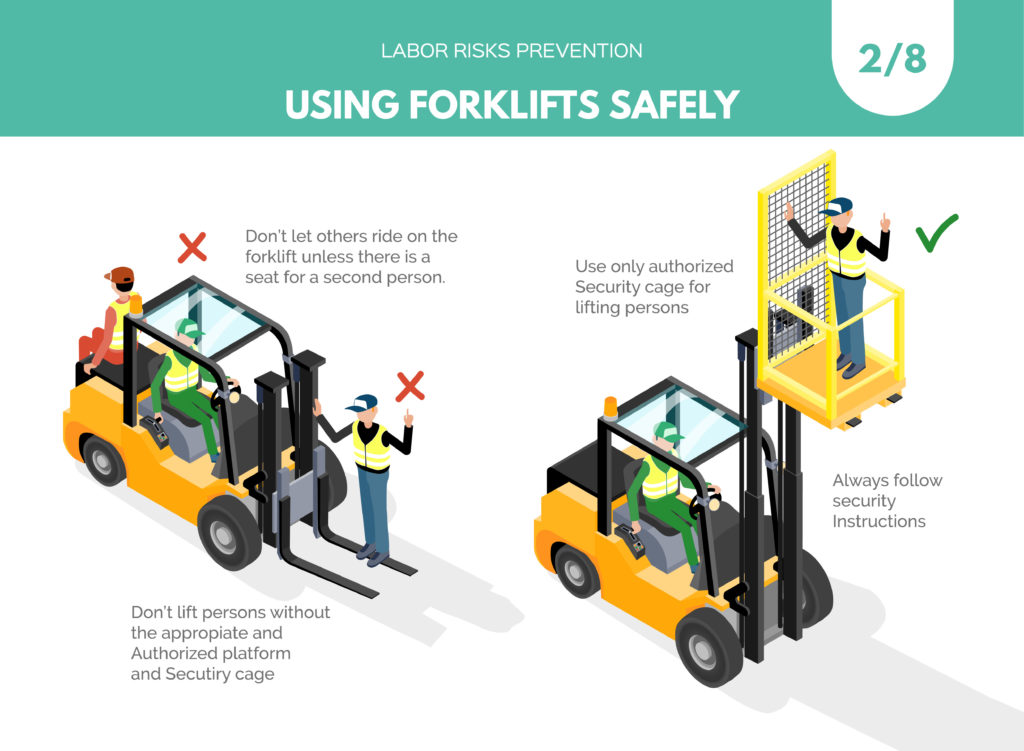

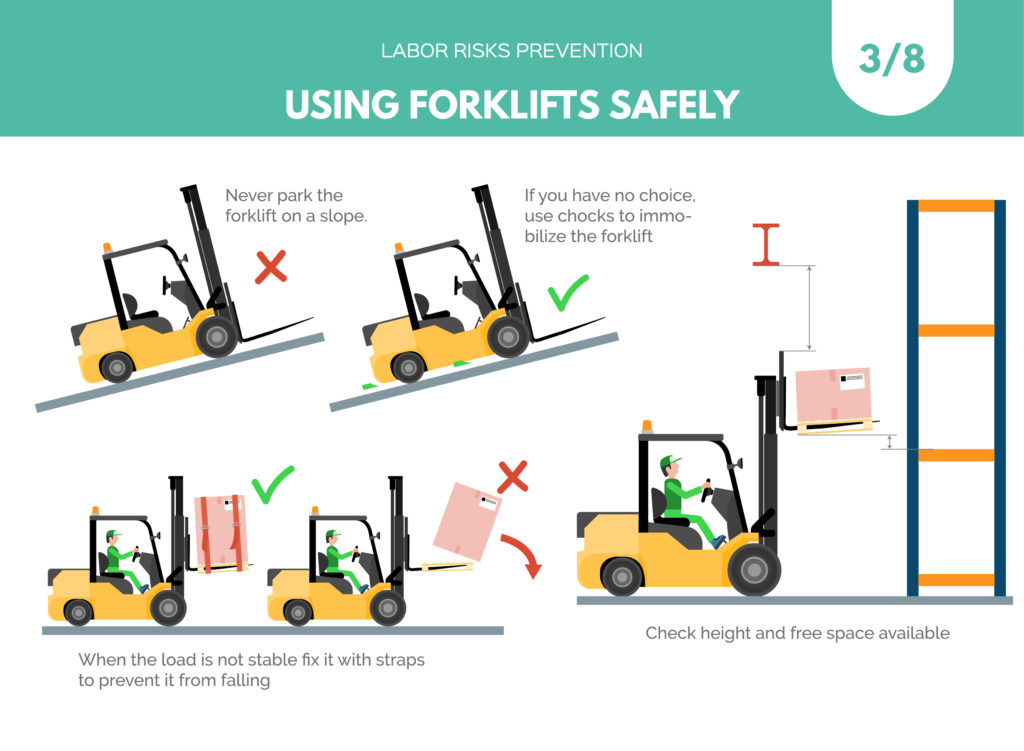

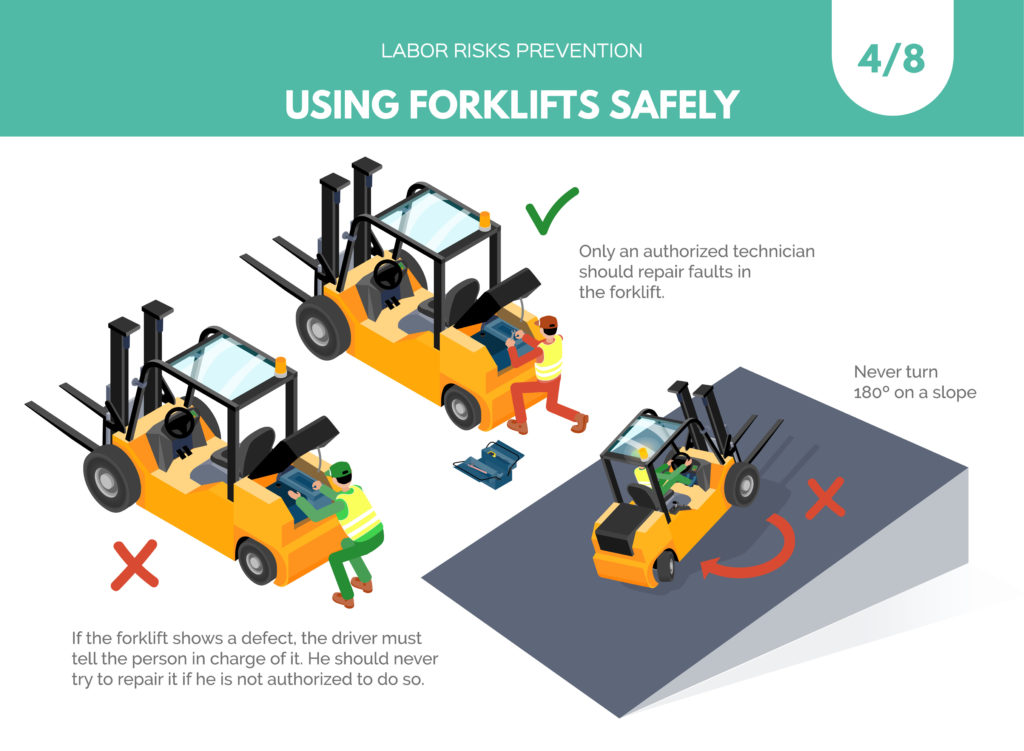

The most common cause of injury or death in forklift accidents comes when the machine tips over. There are many causes for a forklift to tip over; they can tip because the machine is improperly secured or poorly positioned load, but sometimes a load that is way too heavy. A forklift can also tip over if it is on an incline or if the operator turns it too quickly. Another common forklift hazard is related to falls; no one but the operator should ride on the forklift unless there is an extra passenger seat. Another problem; forklifts should never be used to lift people unless the machine has been equipped with an approved lifting cage.

Forklifts are Not Tools; Their Operation Requires Knowledge

There are many issues related to operating a forklift safely, which is why everyone who operates a forklift should be trained and certified on all of them. Besides the potential for poor operation by untrained workers doing the wrong things around a forklift, there is also the potential for design defects. Federal and Texas law basically guarantee all workers a safe place to work, and all parties, including prime contractors, subcontractors, business owners, and property owners, as well as those who manufacturer and maintain forklifts, all have a duty to ensure their safe operation at every worksite where one is used. This is why it’s important to contact a San Antonio workplace injury attorney if you feel unsafe in your workspace.

Injuries from forklift accidents can be extremely severe; they can include concussions and traumatic brain injury (TBI), but they can also include broken bones; deep cuts; crushing injuries; spinal cord injuries, including paralysis; and even death. Many injuries that result from a forklift accident can be life-altering.

If proper forklift training wasn’t provided or if the forklift wasn’t properly maintained, OSHA and some Texas labor laws could provide an accident victim with a way to recover for any damages they incur. In some cases, the forklift might have a design or manufacturing defect, which can make some forklifts unsafe. Prime contractors, subcontractors, property owners, and others also have a duty to ensure forklift safety. A product liability lawyer in San Antonio could help you get money from the manufacturer or others when that becomes necessary.